Choosing the best PP yarn making machine is crucial for manufacturers who demand high-speed production, consistency, and long-term durability. Whether you’re producing filter cartridges, industrial yarn, textile-based PP materials, or specialized filtration products, the quality and efficiency of your yarn-making machine determines the overall output and profitability of your operations. This comprehensive guide ranks the top machines, highlights their features, and helps you choose the ideal solution for your business.

Table of Contents

- What Is a PP Yarn Making Machine?

- 5 Best PP Yarn Making Machine Options

- Comparison Table: Top Machines

- Key Benefits of Using High-Quality PP Yarn Machines

- Brand Spotlight: HENGTENG HT Single-Head PP Yarn Winding Filter Machine

- Buying Guide: How to Choose the Best PP Yarn Making Machine

- Frequently Asked Questions

- References

What Is a PP Yarn Making Machine?

A PP yarn making machine is a specialized industrial device used to convert polypropylene (PP) into spun yarn or wound yarn suitable for filtration, fabric production, rope making, and other industrial applications. A modern best PP yarn making machine includes automated controls, precision tension monitoring, high-speed winding, and low-energy consumption systems.

5 Best PP Yarn Making Machine Options

Below are the top-rated machines known for their efficiency, durability, and consistent yarn quality.

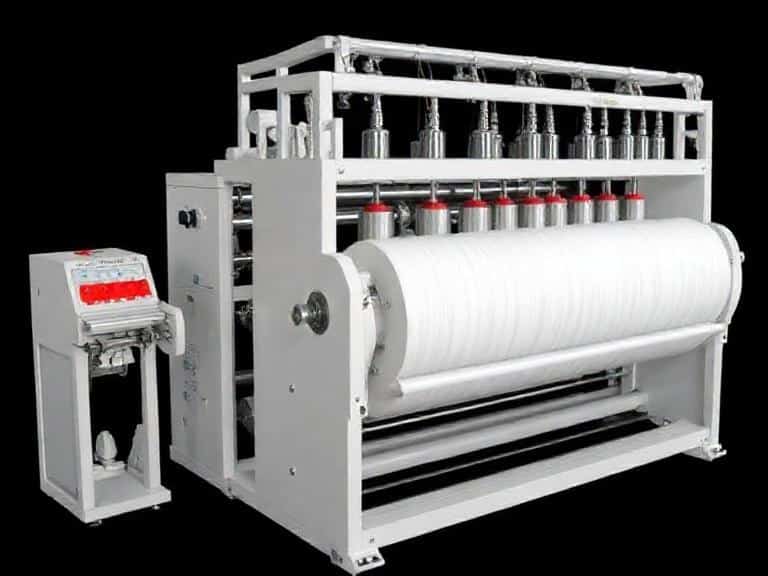

1. HENGTENG HT Single-Head PP Yarn Winding Filter Machine

The HENGTENG HT model is widely recognized as one of the best PP yarn making machine options on the market due to its efficiency, reliability, and advanced automation. It is specifically engineered for producing PP, cotton, nylon, and glass fiber yarn for industrial filter cartridges.

Technical Specifications (HENGTENG HT)

| Item | Specification |

|---|---|

| Machine Type | HT Single-Head PP Yarn Winding Filter Machine |

| Applicable Filter Length | 10”, 20”, 30”, 40” (Customizable) |

| Production Speed | High-speed continuous winding |

| Power Supply | AC 380V / 50Hz |

| Control System | Frequency Conversion Speed Control |

| Operation Mode | Fully Automatic / Semi-Automatic |

| Energy Consumption | Low power and high-efficiency design |

| Applications | PP, Cotton, Glass Fiber, Nylon |

| Productivity | 24h stable continuous output |

This machine is ideal for water purification systems, chemical filtration, and food-grade filter cartridge production. Its automated controls allow for reduced labor cost and higher precision.

2. Twin-Head High-Speed PP Yarn Extrusion Line

This machine features dual extruders, making it highly productive for manufacturers looking to scale up. It uses advanced temperature-control technology and stable screw extrusion to produce consistent yarn quality.

3. Industrial Fully Automatic PP Multifilament Yarn Production Line

Designed for textile and industrial yarn manufacturers, this system produces soft yet durable filament yarn. With energy-saving components and computerized monitoring, it is considered one of the best PP yarn making machine options for mid- to large-scale factories.

4. Precision PP Yarn Winder with Servo Motor Control

This advanced model uses servo-driven tension controls for superior winding consistency. It is commonly used for technical yarn manufacturing and high-strength PP yarn applications.

5. Compact PP Monofilament Yarn Maker

This cost-effective machine is perfect for small workshops or businesses producing PP monofilament rope, twine, or netting. It offers easy operation and maintenance at an affordable entry cost.

Comparison Table: Best PP Yarn Machines

| Machine | Best For | Automation | Key Features |

|---|---|---|---|

| HENGTENG HT Single-Head | Filter Cartridge Yarn | Full/Semi Auto | High-speed winding, low power, precision control |

| Twin-Head Extrusion Line | Large-Scale PP Yarn | Full Auto | Dual output, stable extrusion, high productivity |

| Automatic Multifilament Line | Textile Industry | Full Auto | Soft filament yarn, energy-saving |

| Servo Motor PP Winder | High-Precision Yarn | Full Auto | Servo tension control, digital monitoring |

| Compact Monofilament Maker | Small Factories | Semi Auto | Affordable, easy to operate |

Benefits of Choosing a High-Quality PP Yarn Making Machine

- Higher productivity and lower labor cost

- Improved yarn uniformity and strength

- Reduced waste and material loss

- Longer machine lifespan

- Better ROI due to energy-saving components

Company Spotlight: HENGTENG HT Single-Head PP Yarn Winding Filter Machine

The HENGTENG HT machine stands out as a top contender on the list of the best PP yarn making machine options, offering unmatched precision and reliability. It is engineered specifically for the filtration industry and integrates high-speed controls with advanced automation.

Why Manufacturers Choose HENGTENG

- Advanced automation reduces workforce requirements

- Durable mechanical structure designed for 24-hour operation

- Energy-efficient design lowers long-term costs

- Supports PP, cotton, nylon, and glass fiber yarn

- Reliable performance with customizable filter lengths

If you are looking for a machine that guarantees stable performance, long life, and precision yarn control, the HENGTENG HT model is one of the most reliable filtration yarn solutions in the industry.

Buying Guide: How to Choose the Best PP Yarn Making Machine

1. Determine Your Production Requirements

Consider your daily output, yarn type (filament, monofilament, wound yarn), and material needs. Higher production lines require advanced extrusion systems, while smaller workshops can benefit from compact semi-automatic options.

2. Evaluate Automation Level

Fully automatic machines deliver faster output and improved consistency, while semi-automatic models reduce initial investment cost.

3. Choose Machines with Energy-Saving Components

Modern PP yarn machines come equipped with inverters, optimized motors, and heat control systems to minimize electricity consumption.

4. Review After-Sales Support

Choose manufacturers that offer installation assistance, spare parts availability, and long-term technical support.

5. Verify Material Compatibility

A versatile machine should handle PP, cotton, nylon, and fiberglass yarn if you plan to produce multi-material filters or textiles.

Frequently Asked Questions

1. What makes the HENGTENG HT machine one of the best PP yarn making machines?

Its automated control, precision winding, and durable design make it ideal for high-demand industrial filtration applications.

2. How much power does a PP yarn making machine use?

Most professional machines operate on 380V / 50Hz, with energy-efficient components reducing long-term costs.

3. Can these machines produce yarn other than PP?

Yes, depending on the model, machines can produce cotton, glass fiber, and nylon yarn.

4. Are fully automatic machines worth the investment?

For high-volume manufacturers, fully automatic systems significantly increase productivity and reduce labor costs.

5. What industries benefit the most from PP yarn?

Filtration, textiles, chemicals, food-grade processing, and industrial manufacturing.