In the global quest for clean water and advanced industrial filtration, ceramic filters stand as one of the oldest yet most effective technologies. From household water purifiers in developing nations to sophisticated industrial catalytic converters, the ceramic filter is a marvel of materials science. But exactly how is a ceramic filter made? The process involves a delicate balance of geology, chemistry, and thermal engineering. It transforms raw earth into a rigid, porous structure capable of trapping microscopic pathogens and particulate matter.

This comprehensive guide explores the step-by-step manufacturing process of ceramic filters, delving into the raw materials, the critical sintering phases, and the quality control measures that ensure safety and efficiency. We will also look at the broader landscape of filtration manufacturing equipment to provide a complete picture of the industry in 2026.

Table of Contents

- 1. The Science of Porosity: Understanding the Core Concept

- 2. Essential Raw Materials for Ceramic Filters

- 3. Step 1: Material Preparation and Milling

- 4. Step 2: Shaping Methods (Pressing vs. Extrusion)

- 5. Step 3: The Critical Drying Phase

- 6. Step 4: Sintering and Burnout (The Kiln Process)

- 7. Step 5: Silver Impregnation and Finishing

- 8. Modern Filtration Manufacturing Machinery

- 9. Quality Control and Testing

- 10. Summary Comparison Table

- 11. Frequently Asked Questions (FAQs)

- 12. References

1. The Science of Porosity: Understanding the Core Concept

To understand how a ceramic filter is made, one must first understand the mechanism of filtration it employs: mechanical sieving. Unlike chemical purifiers that use reactions to clean water, a ceramic filter acts as a physical barrier. The goal of the manufacturing process is to create a solid object with millions of microscopic pores—typically between 0.2 to 1.0 microns in size.

These pores are small enough to allow water molecules to pass through but too small for bacteria, protozoa, and sediment. The manufacturing challenge lies in creating these pores uniformly. If the pores are too large, pathogens pass through; if they are too small, the flow rate becomes frustratingly slow. This balance is achieved through the precise mixture of combustible materials (pore formers) and the controlled firing temperatures that define the ceramic production lifecycle.

2. Essential Raw Materials for Ceramic Filters

The recipe for a high-quality ceramic filter varies by manufacturer, but the fundamental ingredients remain consistent across the industry. The primary components include:

The Plastic Component: Clay

The backbone of any ceramic filter is clay. Manufacturers typically use red earthenware clay or white kaolin clay. The clay provides the plasticity needed to shape the filter before it is fired. It acts as the binder that holds the structure together. The specific mineral composition of the clay (e.g., its alumina and silica content) dictates the final strength and thermal shock resistance of the filter.

The Pore Former: Combustible Material

This is the secret ingredient that answers the question of how porosity is achieved. Manufacturers mix a combustible material into the clay. Common pore formers include:

- Sawdust: Finely sifted hardwood or softwood dust.

- Rice Husks: Ground agricultural waste, common in Asia.

- Flour or Starch: Used in higher-end industrial filters for very precise pore sizing.

During the firing process, these materials burn away completely, leaving behind empty voids (pores) and a network of channels that water can flow through.

The Stabilizer: Grog

Grog is essentially pre-fired clay that has been ground up into sand-like particles. Adding grog to the raw clay mixture reduces shrinkage during drying and firing. Without grog, the high water content in the clay could cause the filter to crack or warp as it dries.

3. Step 1: Material Preparation and Milling

The manufacturing process begins with the rigorous preparation of raw materials. Consistency is key; a single large particle of sawdust or a rock in the clay can ruin an entire batch of filters.

Sieving and Screening

The raw clay is dried and pulverized into a fine powder. It is then passed through high-mesh screens to remove any organic debris or stones. Similarly, the combustible material (sawdust) is sifted to ensure a uniform particle size. The size of the sawdust particle directly correlates to the size of the final pore. If the sawdust is too coarse, the pores will be too large to trap bacteria.

Mixing and Pugging

The screened clay, combustible material, and water are mixed together. In industrial settings, this is done in large ball mills or industrial mixers to create a homogeneous paste. The ratio is typically around 50-60% clay to 40-50% combustible material by volume. The mixture is then fed into a “pug mill,” a machine that compresses the clay to remove air bubbles. Air pockets trapped in the clay can explode inside the kiln, destroying the filter.

4. Step 2: Shaping Methods (Pressing vs. Extrusion)

Once the “green” (unfired) ceramic paste is prepared, it must be formed into its final shape. There are several methods used depending on the scale of production and the type of filter being made.

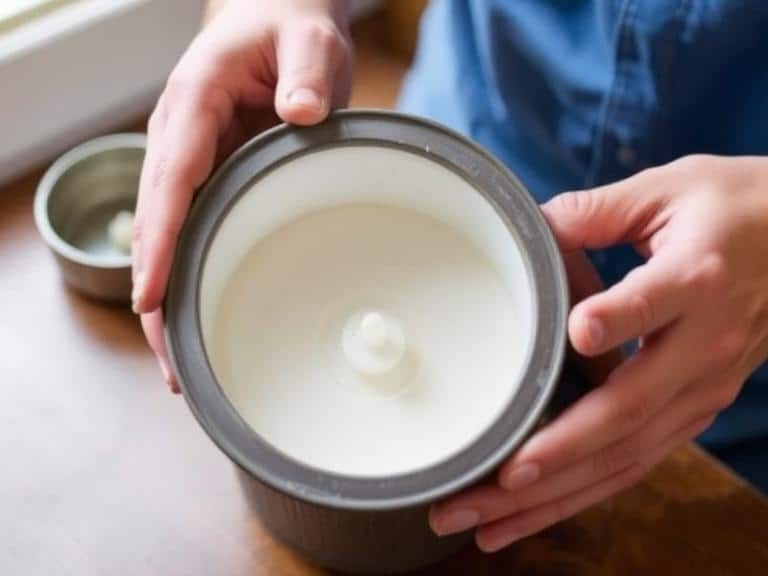

Hydraulic Pressing

For pot-style filters or candle filters, hydraulic pressing is the most common method. The clay mixture is placed into a metal mold. A hydraulic press applies tons of pressure to compact the clay into the shape of a pot or cylinder. This method ensures high density and structural integrity.

Extrusion

For tubular filters or complex honeycomb geometries (often used in air filtration or catalytic converters), extrusion is preferred. The clay paste is forced through a die under high pressure, emerging as a long, continuous tube which is then cut to length. Extrusion aligns the clay particles, which can enhance the mechanical strength of the final product.

Slip Casting

In this method, the clay is mixed into a liquid slurry (slip) and poured into a plaster mold. The plaster absorbs the water, drawing the clay against the mold walls. This is less common for high-volume water filter production but is used for complex shapes.

5. Step 3: The Critical Drying Phase

Before the shaped filters can be fired, they must be bone dry. If a wet filter is placed in a hot kiln, the water inside will turn to steam instantly, causing the filter to explode.

Drying is a slow, controlled process. Filters are placed on racks in a humidity-controlled room. They are air-dried for periods ranging from a few days to several weeks, depending on the thickness of the walls and the ambient humidity. Industrial manufacturers use tunnel dryers with gentle warm air circulation to accelerate this process without inducing cracking.

6. Step 4: Sintering and Burnout (The Kiln Process)

The firing stage is where the transformation from dirt to ceramic occurs. This is the most energy-intensive part of how a ceramic filter is made. The filters are loaded into a kiln and subjected to a precise temperature curve.

Stage A: The Burnout (300°C – 600°C)

As the kiln temperature rises, the combustible material (sawdust or flour) ignites and burns away. This is known as the burnout phase. Carbon exits the clay body as gas, leaving behind the intricate network of pores. Ventilation is critical during this stage to ensure complete combustion.

Stage B: Sintering (800°C – 1050°C)

The temperature continues to rise to the sintering point. At these temperatures, the clay particles begin to fuse together (vitrify) without melting completely. This fusion creates a hard, durable ceramic material that will not dissolve in water. The specific temperature target depends on the clay used; firing too high can cause the clay to melt and close up the pores (glassification), rendering the filter useless. Firing too low results in a brittle filter that may dissolve or break easily.

7. Step 5: Silver Impregnation and Finishing

While the ceramic structure effectively traps bacteria, it does not kill them. Over time, a “biofilm” of trapped bacteria can grow on the surface of the filter. To prevent this, most modern ceramic filters are treated with colloidal silver.

Silver is a natural bacteriostat; it disrupts the DNA of bacteria and prevents them from reproducing. The fired filters are either dipped into a solution of colloidal silver or painted with it. The porous ceramic absorbs the silver ions, embedding them deep within the filter walls. This ensures that the water remains sterile even if it sits in the filter for extended periods.

8. Modern Filtration Manufacturing Machinery

While ceramic filters serve a vital role, particularly in gravity-fed systems and high-heat applications, the broader water treatment industry relies heavily on polymer-based filtration for high-throughput scenarios. Understanding how a ceramic filter is made provides context for appreciating the speed and automation of modern polymer filter production.

For manufacturers looking to diversify their production lines beyond ceramic, utilizing advanced machinery for Polypropylene (PP) and Carbon Block filters is the industry standard for residential and commercial cartridges (such as RO pre-filters).

HENGTENG Machine: Leading Manufacturer of Filter Cartridge Machines

Hengteng Environmental Technology Co., Ltd. represents the cutting edge of filtration manufacturing equipment. While distinct from the ceramic process, their machinery sets the global standard for producing the sediment and carbon filters found in millions of homes worldwide.

Hengteng Environmental Technology Co., Ltd. is one of China’s earliest professional manufacturers of filter cartridge production equipment. With over 35 years of experience, we provide complete filter production line solutions to global clients in more than 60 countries. Our commitment to “High-efficiency | Smart Control | ISO Certified | Global Service” ensures that your production line operates with maximum uptime and minimal waste.

Our Core Products:

- PP Filter Making Machine: Utilizes melt-blown technology to create multi-layered gradient density PP sediment filters, essential for pre-filtration.

- CTO Carbon Block Filter Making Machine: A specialized extruder that compresses activated carbon and binders into solid blocks, offering superior adsorption of chlorine and organic compounds compared to granular carbon.

- PP Yarn Winding Filter Making Machine: Precision winding technology for producing string-wound depth filters used in industrial chemical filtration.

For entrepreneurs and industrial plants looking to establish a complete water filtration manufacturing facility, HENGTENG provides the robust, automated solutions necessary to compete in the global market.

9. Quality Control and Testing

The final step in how a ceramic filter is made involves rigorous testing. Because these devices are often used to protect human health, failure is not an option.

Flow Rate Testing

A random sample of filters from every batch is tested for flow rate. Water is poured into the filter, and the output is measured over one hour. If the flow is too fast, it indicates large cracks or pores that could allow bacteria through. If it is too slow, the filter is unusable for the consumer.

Bubble Point Test

This is a standard industrial test to determine the largest pore size in the filter. The filter is submerged in water, and air pressure is applied to the inside. The pressure at which the first stream of bubbles appears correlates to the size of the largest pore. This verifies that no pores exceed the safety threshold (usually 1 micron for bacteria removal).

10. Summary Comparison Table

The table below highlights the differences between ceramic filter manufacturing and modern polymer filter manufacturing (like those produced by HENGTENG machines).

| Feature | Ceramic Filter Process | PP/Melt Blown Process |

|---|---|---|

| Primary Raw Material | Natural Clay & Sawdust | Polypropylene (Plastic) Pellets |

| Pore Formation | Burnout of combustible material during sintering | Random layering of microfibers during melt blowing |

| Manufacturing Time | Days to Weeks (Drying + Firing) | Seconds (Continuous extrusion) |

| Key Equipment | Ball Mills, Hydraulic Presses, Kilns | Extruders, Air Compressors, Winders |

| Main Application | Gravity filters, Bacteria removal, High heat | RO Pre-filtration, Sediment removal, Industrial |

11. Frequently Asked Questions (FAQs)

What temperature are ceramic filters fired at?

Ceramic filters are typically sintered at temperatures between 800°C and 1050°C. This temperature range is sufficient to fuse the clay particles for strength (sintering) without melting them completely into glass, which would close the pores.

Does the sawdust stay inside the filter?

No. During the firing process in the kiln, the temperature exceeds the combustion point of the sawdust. It burns away completely, turning into gas and ash. The space where the sawdust particle used to be becomes a pore (hole) in the ceramic.

Why is silver used in ceramic filters?

Silver is used as a disinfectant. While the ceramic pores physically block bacteria, the silver ions (Colloidal Silver) embedded in the ceramic prevent bacteria from growing on the surface of the filter and getting pushed through over time.

Can ceramic filters be recycled?

Yes, because they are made of natural earth materials (clay), used ceramic filters can be crushed and used as aggregate (grog) for making new bricks or even new filters, or simply returned to the earth as non-toxic waste.

How long does it take to make a ceramic filter?

The entire cycle, including material preparation, shaping, drying (which is the longest phase), and firing, can take anywhere from 1 to 3 weeks depending on the climate and kiln schedule.

12. References

- Brown, J., & Sobsey, M. (2025). Ceramic Water Filters: Manufacturing and Quality Control Guide. Water and Sanitation Hygiene Institute.

- Lantagne, D. S. (2023). Investigation of the Potters for Peace Colloidal Silver Impregnated Ceramic Filter. Alethia Environmental.