Expert Services

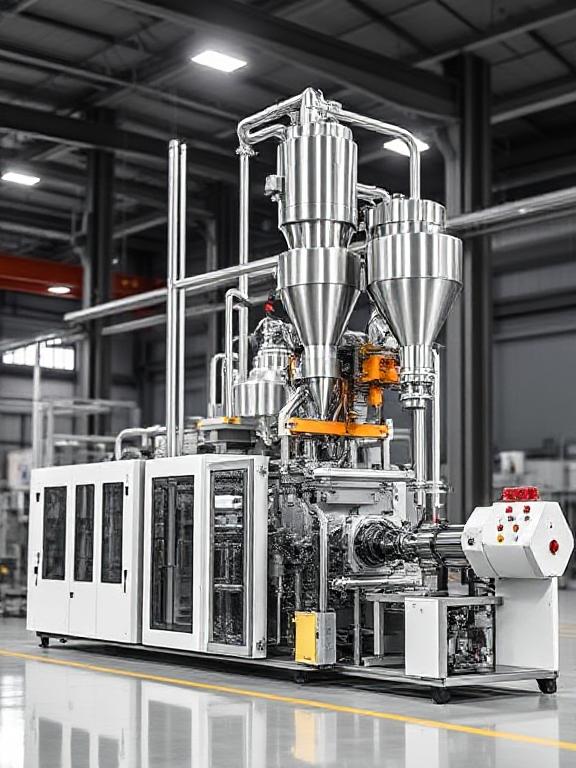

Filter Cartridge Production Line Solutions

Custom Design & Engineering Service

Every client’s production demand is different — that’s why HENGTENG provides customized machine design and production line planning.

Our Design Services Include:

Tailor-made equipment layout according to your plant area and capacity requirements

Selection of machine models for PP melt blown, CTO carbon block, PP yarn winding, and UDF filters

Optimization of process parameters for maximum efficiency and product quality

Integration of automatic feeding, winding, cutting, and packaging systems

Our engineers will evaluate your project needs and design a complete filtration element production line that ensures high output and stable performance.

Equipment Manufacturing & Quality Control

We produce all filter cartridge machines in-house under strict quality management.

What You Can Expect:

ISO9001-certified production process

Five-step quality inspection before shipment

Precision machining with CNC equipment

Strict testing for performance, safety, and energy efficiency

Each HENGTENG filter cartridge making machine is built for long service life, stable operation, and easy maintenance.

Ready to Enhance Your Production?

Installation & Commissioning Service

Once your machines are shipped, our experienced engineers will ensure smooth installation and startup.

We Provide:

On-site equipment installation and system connection

Machine calibration, performance testing, and trial operation

Technical parameter setup for your specific filter types

Operator guidance and maintenance training

Our team can dispatch technicians worldwide to support your factory installation and ensure your new filter cartridge production line runs perfectly from day one.

Technical Training & Operation Guidance

To help your team achieve efficient and safe operation, HENGTENG offers comprehensive technical training both online and on-site.

Training Includes:

Equipment operating procedures

Filter cartridge production techniques

Routine maintenance and troubleshooting

System upgrades and optimization

All training is conducted by senior engineers with deep experience in filter manufacturing, ensuring your operators quickly master production know-how.

Ready to Enhance Your Production?

After-Sales Service & Maintenance

At HENGTENG, our service continues long after your machines are delivered.

Our After-Sales Commitments:

24-hour customer response

Online technical consultation and remote diagnosis

Quick supply of spare parts and consumables

Regular maintenance and performance review

Lifetime technical support

If your filter cartridge machine needs assistance, our customer service center and engineering team are always available to provide reliable solutions — ensuring your production line operates without interruption.

Upgrading & Optimization Service

We help clients upgrade existing filter production lines to improve output and reduce costs.

Upgrade Options:

Automation system updates

Energy-saving extrusion system

New model retrofitting for higher accuracy

Integration of automatic packaging lines

With decades of manufacturing and engineering experience, HENGTENG ensures that your equipment remains competitive, efficient, and future-ready.